If your South Florida home is over 10 years old, more than likely you have Fiberglass Duct Work in your home. But wait, what exactly is fiberglass?

Fiberglass also known as Fiber Board or Duct Board is a common type of fiber-reinforced material made of glass, like windows or the drinking glasses in the kitchen. The glass is heated until it is molten, then it is forced through superfine holes, creating glass filaments that are very thin – so thin they are better measured in microns. The fibers may be randomly arranged, flattened into a sheet (called a chopped strand mat), or woven into a fabric. The plastic matrix may be a thermoset polymer matrix—most often based on thermosetting polymers such as epoxy, polyester resin, or vinylester—or a thermoplastic.

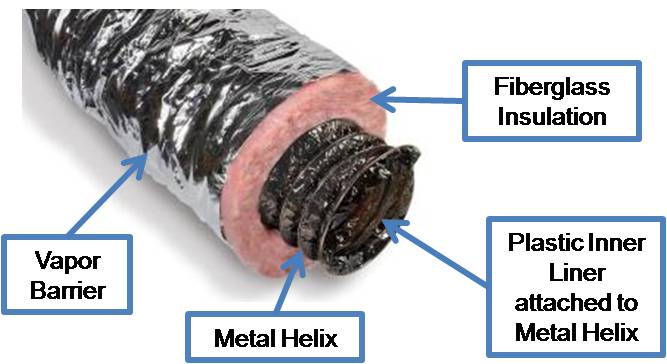

For nearly 50 years, fiberglass insulation has been used as a component of air duct systems to maintain comfort and IAQ. HVAC fiberglass insulation meets four requirements of a duct system:

- Temperature control — Delivering heated or cooled air at the temperature level best suited to building needs;

- Acoustical control — Absorbing noise generated by air-handling equipment and by air moving through ducts;

- Condensation control — Preventing condensation that could damage insulation and other HVAC system components or possibly lead to microbial growth; and

- Energy conservation — Reducing HVAC system operating costs and energy use by lowering heat loss or gain through the air duct wall.

Although new materials are introduced from time to time to serve as new HVAC duct system materials, the fact is that nearly all duct insulation products continue to use fiberglass technology, for reasons of safety, cost effectiveness, and performance.

In 1994, OSHA issued the first federal proposal for comprehensive regulation of indoor air quality (IAQ). It addressed the 30 percent of all “non-industrial work environments” believed to have IAQ problems. OSHA outlined a detailed inspection and compliance program of maintenance, ventilation, relative humidity, and carbon dioxide control. Its goal was to significantly reduce the incidence of “sick building syndrome” and the bacterial infection known as Legionnaire’s Disease.

With Indoor Air Quality in mind and the use of IAQ Fiberlock 8000, an EPA registered material, our Mold Resistant Fiberglass Coating service would not only prohibit the growth of mold, mildew and other microbial contaminants in your duct work. It also resurfaces and reinforce the fibers in your ducting system. This is most beneficial to slow down the deterioration of your fiberglass duct work and ensure you are not breathing any fiberglass in the air.

At DUCTZ of N Lauderdale & Pompano Beach, we strive to provide the best solution when catering to your Indoor Air Quality needs. Call us at (954) 366-6131 and speak to one of our IAQ expert today for your

FREE Visual Inspection!